Test & Assess

spraying configurations for optimal drone spraying applications in field conditions.

Compare

existing conventional with drone spraying practices regarding their efficiency and environmental impact.

Identify

risks and develop mitigation strategies related to drone-based plant protection applications.

Drone spraying

The scope of the UC2 is to test and assess spraying configurations for optimal drone spraying applications in field conditions. To this end, the experimental design focuses on both the evaluation of spraying quality (i.e., deposition, canopy penetration and spray drift) achieved through various operational configurations (i.e., spraying altitude, speed, nozzle flow and liquid deposition rates) for spraying drones, as well as their comparison with existing conventional spraying machinery, such as conventional terrestrial boom and mist sprayers. Finally, the UC2 aims to identify inherent risks of drone spraying and address them through the development of novel mitigation strategies, enabling safe and eco-friendly drone-based plant protection applications.

Technical Requirements

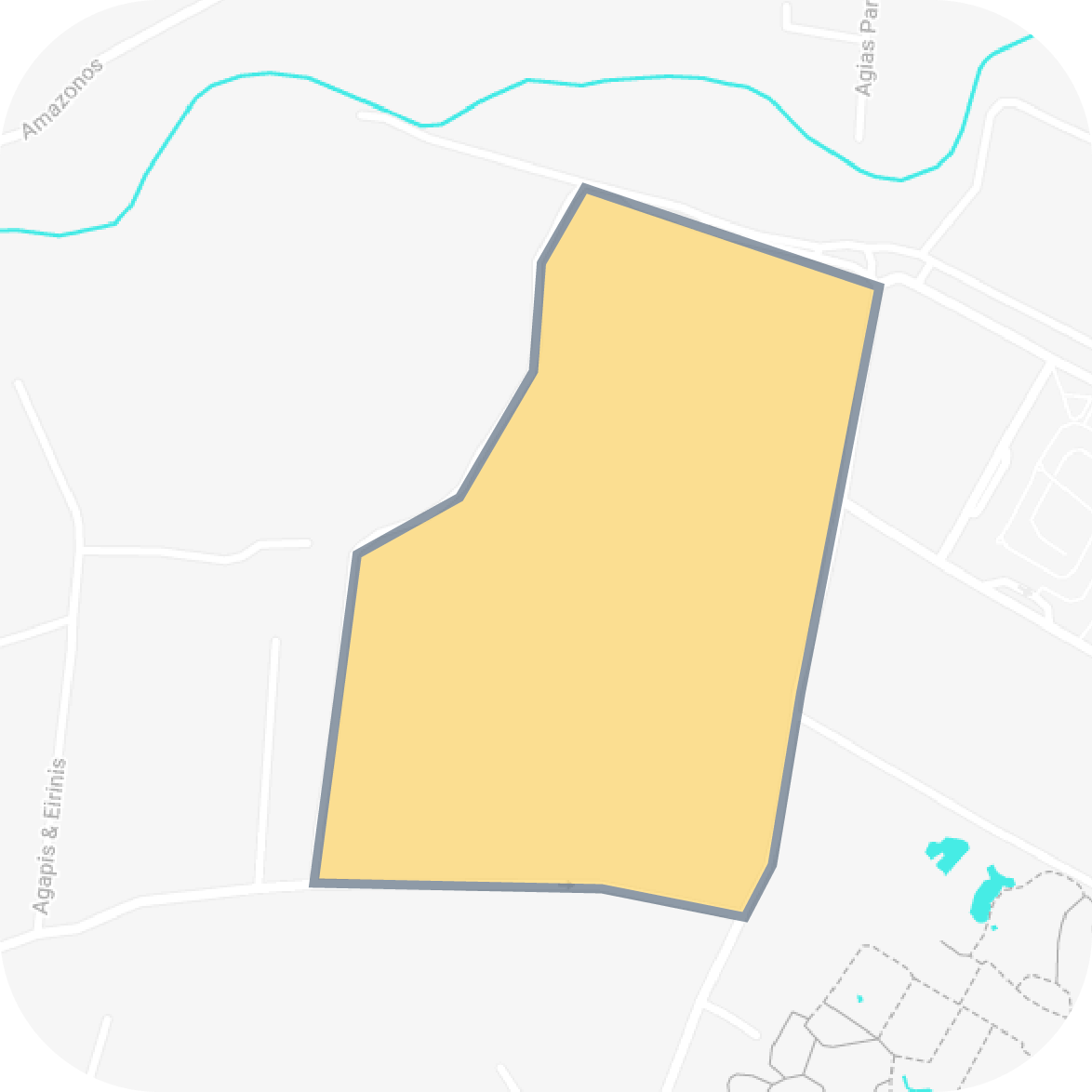

Pilot & Test Area

Area: Spata, Greece

(37°59'06" N, 23°54'21" E)

120 hectares of viticulture production for varied species

- DJI Agras T16

- DJI Agras T10

- Integrated guidance systems and light-control instruments

Methodology

Drone Spraying Quality

The drone’s performance will be evaluated in two different application methods, namely by flying over the inter-row and by spraying over a single row. The collectors used for the sampling of spraying droplets are WSPs of 0.76 mm x 26 mm that intercept the spray droplets and instantly change colour upon contact with liquid. Three canopy WSPs will be placed inside each row at three heights stabilised to the trellis: 0.3 m, 0.6 m, and 1 m in order to evaluate the droplet distribution of each strategy / set of configurations. Moreover, ground WSPs placed on dedicated wooden supports are used to evaluate wasted agrochemicals that did not reach the vegetation but dropped on the soils instead. For this application, no tracer is required for data collection, and therefore spraying is conducted with deionised water. The WSPs sprayed by the UAV are collected one minute after the distribution and stored in a specific designed box for preventing colour changes due to moisture, and in individual sampling bags to prevent contact between papers. The samples are then analysed with an image processing software to determine the DV10, DV50, and DV90 by using the image processing system, namely DepositScan developed by USDA.

Drone Spraying Drift

The field experiments were carried out based on a UAV-adapted version of the ISO 22866:2005 standard, which set the criteria on the conditions for spray drift measurements. In accordance with this, the directly-sprayed area is 30 m wide upwind of the edge of the cropped area. For these trials, water is mixed with a coloured tracer (high purity tartrazine - E102) used to fill the spraying tank at a concentration of 4 g/L. Moreover, weather conditions are constantly measured at 1Hz frequency (1 reading per second) during the entire duration of each experimental flight, at a point near to the test site and 15 m off the flight path in the direction of the wind and height of 2 m. Ambient dry temperature should be between 10 °C and 35 °C, relative humidity should not exceed 70% and the mean wind speed should be under 2.0 m/s. The test must be stopped if wind speed exceeds 3 m/s at any point during spraying.In each drift trial, ground sediment droplets downwind to the directly-sprayed area are sampled. The ground collectors are placed at 12 different sampling distances in bare soil at 1, 2, 3, 4, 5, 7.5, 10, 12.5, 15, 20, 25, and 30 m from the end of the directly-sprayed area. These distances started from the parallel straight line in front of the last plant row spaced 1 m. At each sampling distance, three wooden laths were placed with an upper surface covered in filter paper, Whatman Grade-1, 46 x 8 cm.